Navus to Host Free Cobot Welder Demonstration

What would you say if we told you that we could solve your need for more skilled welders while increasing productivity and quality, ultimately enabling you to accept more welding jobs? It may sound too good to be true, but with Hirebotics’ Cobot Welder, all of these things are possible. On May 25, 2022 Navus will be hosting a free demonstration at our Hardin Valley facility to showcase all of the amazing possibilities of the Cobot Welder.

Current Challenges of the Welding Industry

In today’s job market, finding the right welders for your team can be challenging. Demand of talent is high and ever-increasing, while the pool of available talent remains low. Navus has had its own struggles in recruiting efforts this year. That’s why we started looking for sustainable solutions to add more welding power to our team while the job market is over-saturated with opportunities.

We have been more than impressed with the Cobot Welder’s ability to fill the gap on our welding needs. It’s enabled us to finish projects more quickly without compromising our standards of quality, ultimately unlocking more opportunities for our company.

Automation Built for Welders, Not Robot Programmers

The Cobot Welder is built specifically for welders to use and understand. Your team won’t have to rely on a robot programmer to program the welding tool. In fact, it’s developed so your welding team can program it without the help of anyone else.

At the end of the day, the Cobot Welder doesn’t replace your actual welders. This solution enhances your entire welding team without taking anything away from the welders who have invested their entire careers with your organization. The result is welding automation that’s built for speed, productivity, and quality.

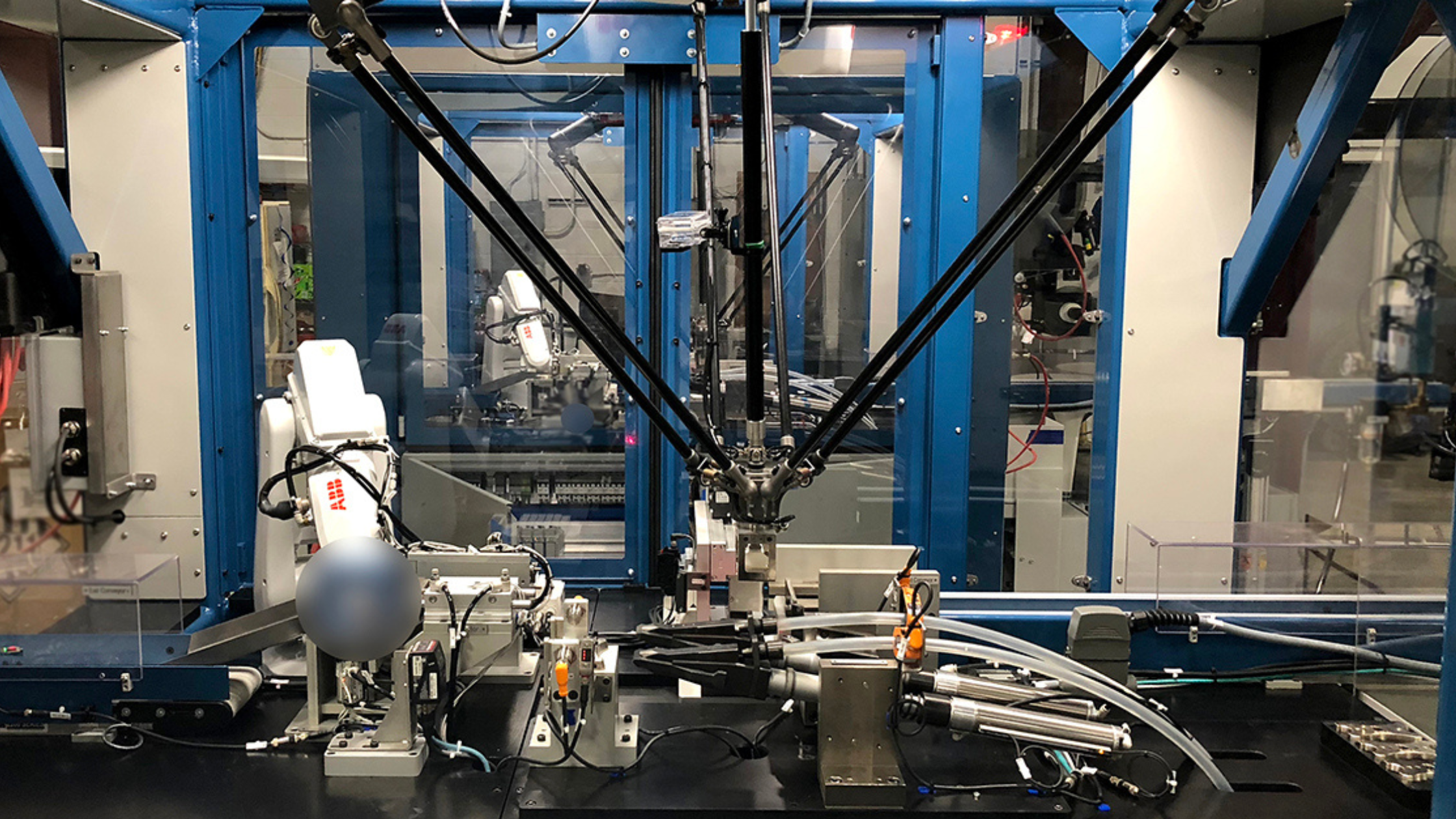

Welding with Collaborative Robots

Unlike industrial robots (like the kind used in lines for large automotive companies), humans and collaborative robots can work in the same space. They’re ideal solutions for smaller companies with a low-volume, high-mix production. You can automate as little or as much of your process as you want! Using collaborative robots to supplement your welding needs can result in:

- Increased capacity & boosted productivity

- Cost savings & flexibility

- Consistent quality

- Easy maintenance

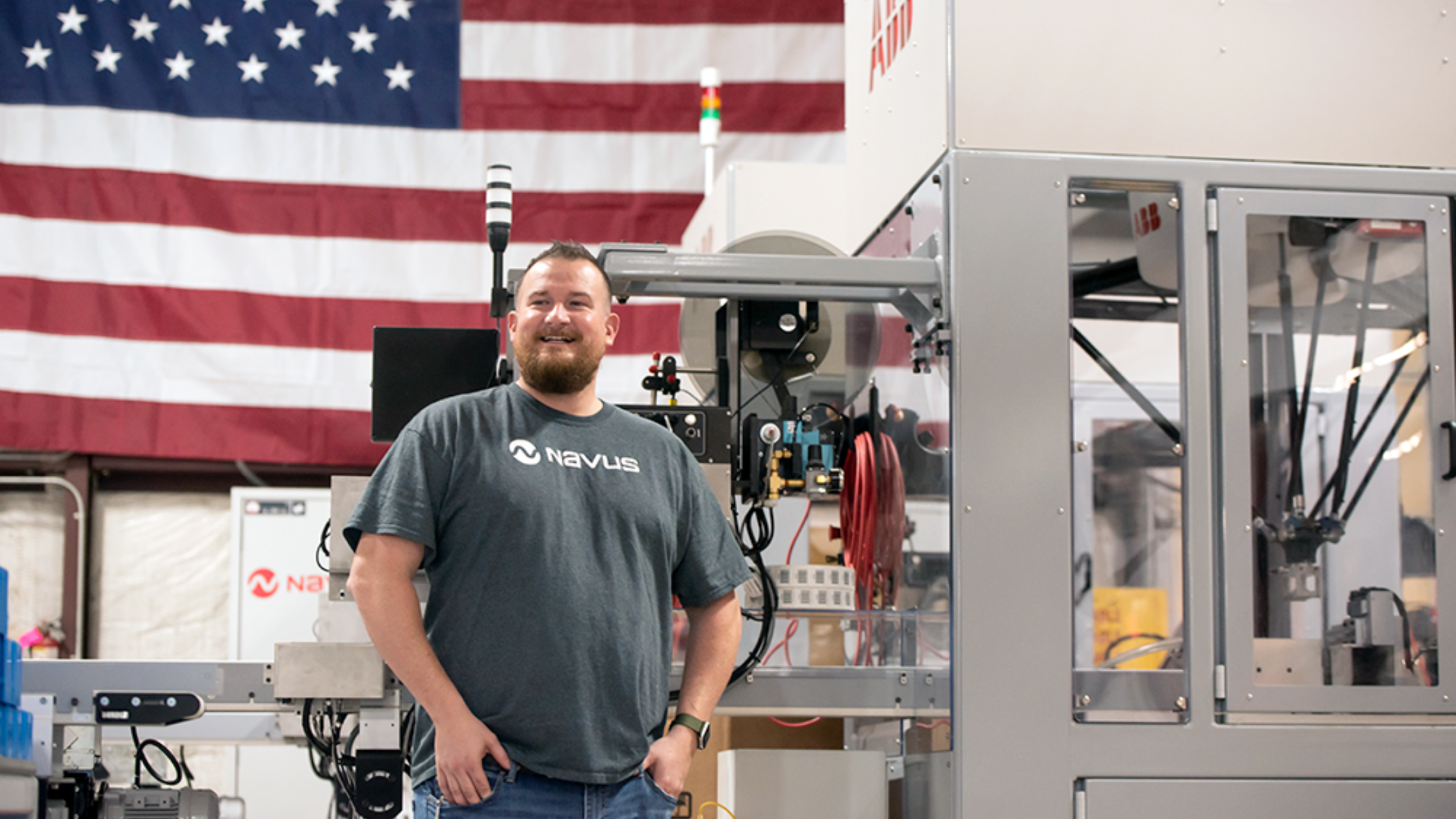

Navus has started using Hirebotics’ Cobot Welders at our own facility, and we’re thrilled to announce an exciting opportunity for our friends and colleagues in the welding industry.

Automated Welding Demonstration at Navus in Knoxville, TN

Navus will be hosting a welding demonstration of the Cobot Welder on May 25, 2022 at our facility in Knoxville, TN. A welding cobot supplier from Hirebotics will be offering training sessions. Anyone can learn how to work with the Cobot Welder in as little as 15 minutes. We’ll also be offering our space the following day for private demonstrations for those who are interested in learning more!

We believe in the opportunities this solution has created for our own team, and we knew we wanted to share it with others who could benefit. We cannot wait to share this solution with like-minded leaders in the industry. We’ll be showing demonstrations from 8 a.m. to 5 p.m. on May 25, 2022. Register today! We’re looking forward to seeing you. In the meantime, if you have any questions, connect with us on our website!