While Navus is known for custom automation solutions, these systems can often be complex and require large capital investment. Using a unique skill set and toolset, Navus can bring key processes to life with scaled demonstrations using a combination of industrial robots, manufacturing, and automation technologies. This allows our clients to fully analyze the risks and rewards of a concept before having to fully commit valuable time and resources.

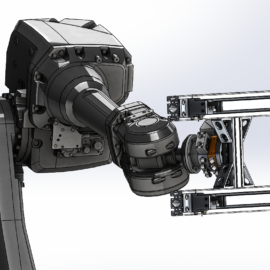

Simulation

Navus uses state of the art offline programming and simulation software to determine the feasibility of an idea before the first part ever needs to be cut, fabricated, machined, or coated. Whether to verify cycle time or ensure proper robot reach and accessibility, this serves to further mitigate risk before building even small-scale test setups.

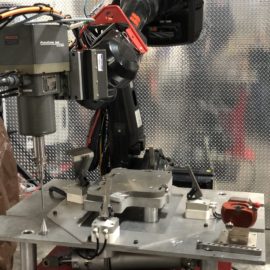

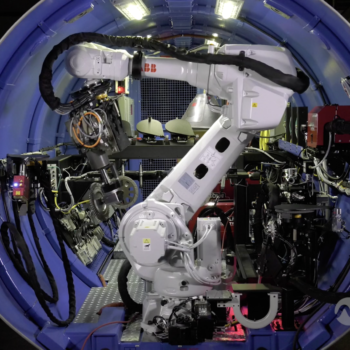

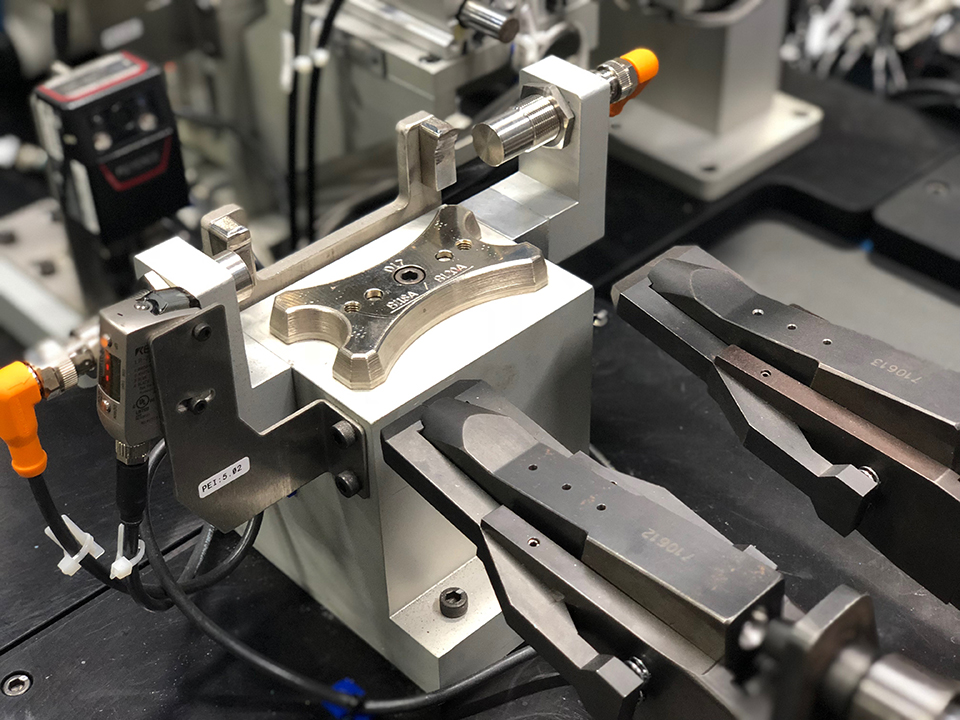

Demonstration

By utilizing our in-house 6-axis industrial robots, PLCs, end of arm tooling, laser scanning/searching technology, force compliant grinding technology, welding capabilities, and custom programming, our clients can realize the process so they can be fully confident before deploying new technology.

Get started today!

Contact us today and discover how we leverage our unique capabilities to help you operate to the best of your abilities.