Project Detail

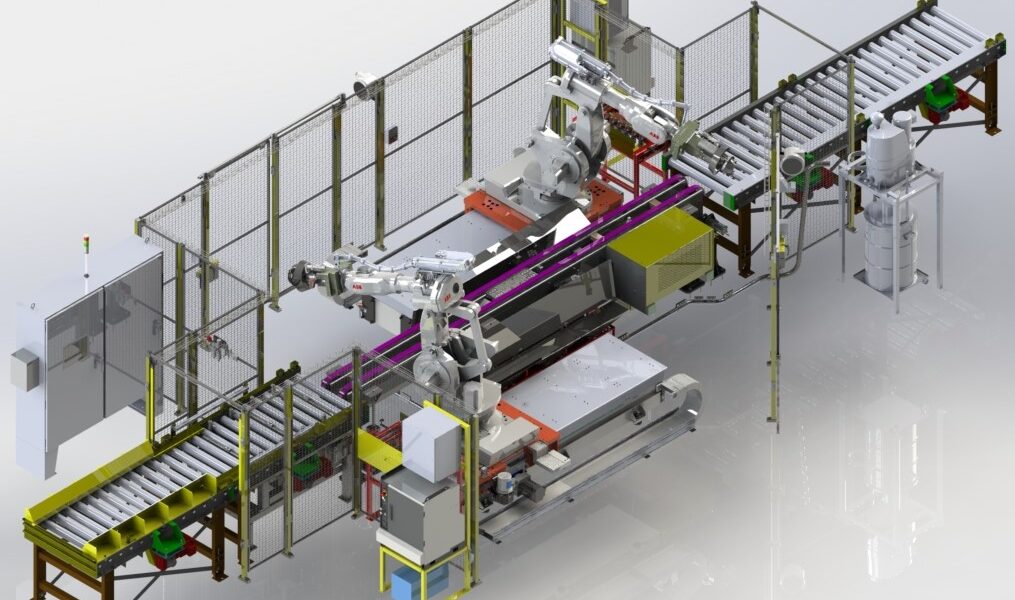

Using sensor guided robotics, this system is designed to locate individual parts that weighed up to 14,000 pounds, identify the part by recognizing its shape and features, create a tool path for it, and then mill the sharp edges on the part to a precise radius.

The Aim

Optimize the automation manufacturing process through faster production times and decreased safety risks for employees.

The Outcome

Successful. Accomplished a production time of less than half the time our client required.