White Paper: Increasing Productivity in Manufacturing with New Weld Technology

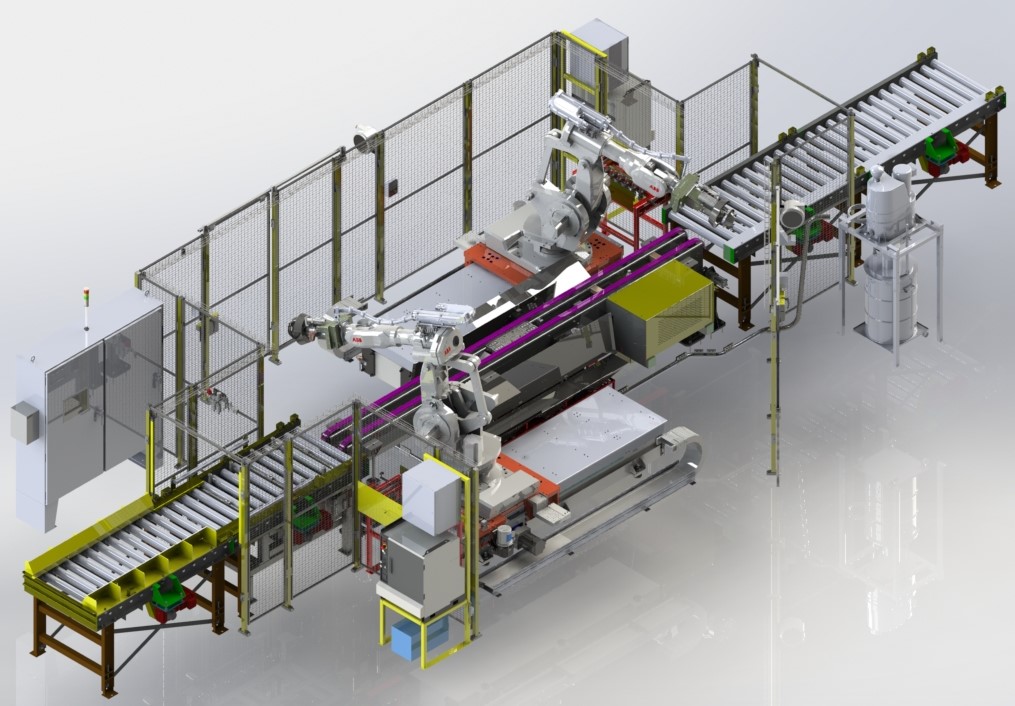

Heavy-industry manufacturing lines will always need the ability to weld heavy and complex parts well. The ability to weld around the circumference of a heavy part in manufacturing is a complicated process. One of the newest projects we’ve finished this year has revolutionized our client’s welding process, opening up new possibilities for the future of their company and manufacturing process.

The latest free white paper we’ve published features a heavy-industry project that transformed an unreliable and outdated welding system into a safer, more accurate weld cell that doubled our client’s productivity. Our client’s old system had a history of parts slipping during the welding process, despite using 15,000 lbs of force to keep parts in place.

Any system that produces imperfect parts during the manufacturing process will slow down production and affect a company’s overall throughput. Our client knew they needed a solution that produced accurate welds, kept parts in place during the process, and kept their line operators safe.

Our engineers are experts at designing new processes that overcome any challenges our clients bring us. This project turned into a special opportunity for us to partner with Miller Electric to beta test a brand new welding system that is the first of its kind on the market! Our team also created a unique spring-loaded tool system that solved our client’s particular frustrations with parts slipping with their old system.

Our client needed a process that could hold parts ranging from 50 to 1,500 lbs without slipping or damaging the part itself. Our solution also needed to automatically recognize parts of different sizes and choose the correct steps and tools for each individual part without manual input. The automated solution required a faster welding system that decreased risk of:

- Porosity

- Cracking and other quality issues

- Decreased risk of part slippage

- Adaptability of the welding process for a variety of complex parts

Though the goal for this project felt complicated and impossible at times, our engineering team knew they could design a system that met all of our client’s needs, increase productivity, and decrease safety risks for employees and operators close to the process. The result of our engineers’ expertise was an easy-to-use-system that integrated with their other processes to deliver finished products faster than they thought possible.

In this free white paper, you’ll discover how this custom, adaptable system:

- Saves time and money through reliable tooling

- Reduces risk of production being stalled because of imperfections in welded parts

- Saves time through a unique, advanced welding technology from Miller Electric

- Reduces safety risks to employees through remote operation

To discover more about how Navus engineers used a cutting-edge welding system to design a custom automation process that worked for our client’s needs, you can read all about it in the free white paper, Increasing Productivity in Manufacturing with New Weld Technology.

Navus Automation Inc. is a leading full-service automation integrator. Our world-class team has a reputation for applying ingenuity to solve complex challenges and deliver customized turn-key systems solutions. From concept to completion, Navus provides robotic welding and automation systems built upon our unwavering commitment to excellence, precision and reliability