Light Industrial Manufacturing: A Navus Visual Case Study

At Navus, we pride ourselves on our ability to meet whatever light industrial manufacturing challenges our clients may throw at us. Whether you’re interested in additive manufacturing, decreased safety risks, or just want to improve throughput, our engineers are ready to help you achieve your goals.

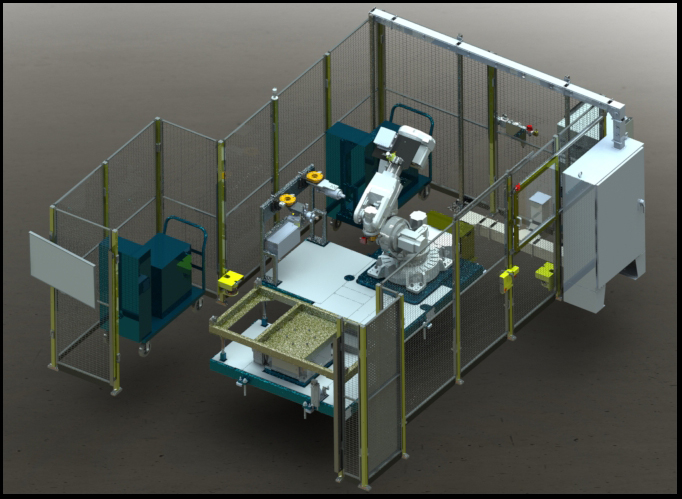

A client recently approached us about implementing automated processes to increase their production time. We partnered with ABB Robotics and CTM Labeling Systems to create a system that sorts the parts and puts them together. This new system increased their production to a rate of 24 finished parts per minute with the ability to have future layouts that won’t require changing their floor space requirements.

Goal: Update an Existing Light Industrial Manufacturing Process

A client recently presented us with an interesting challenge: utilize automation to improve production time in a complicated, multi-step light industrial manufacturing process. They wanted to speed up each part of the automation process to be completed in less than 2.5 seconds.

However, the automation system needed to be flexible in order to account for all the different parts of the production process. Another challenge was cost savings and efficiency. Our client wanted to automate the assembly process in line with their existing equipment without having to change their facility’s floor plan.

This required our system to:

- Operate from a remote control panel

- Rely on a flexible automation process connected to other processes within the facility

- Automate the label application process

- Insert nails into the part

- Correctly nest different parts together

- Monitor processes in real-time

On top of that, the system would need to be able to conduct a robotic quality check. This would ensure that nails would be inserted at a certain depth and parts would be nested correctly.

Click here our top 5 free custom automation resources!

Our Solution

Our team of Navus engineers partnered with ABB Robotics and CTM Labeling Systems to bring our client’s vision to life. They were able to develop a machine that fits in line with other pre-existing light industrial manufacturing processes to increase affordability. They were also able to achieve this without changing the floor plan of the client’s manufacturing facility.

How It Works

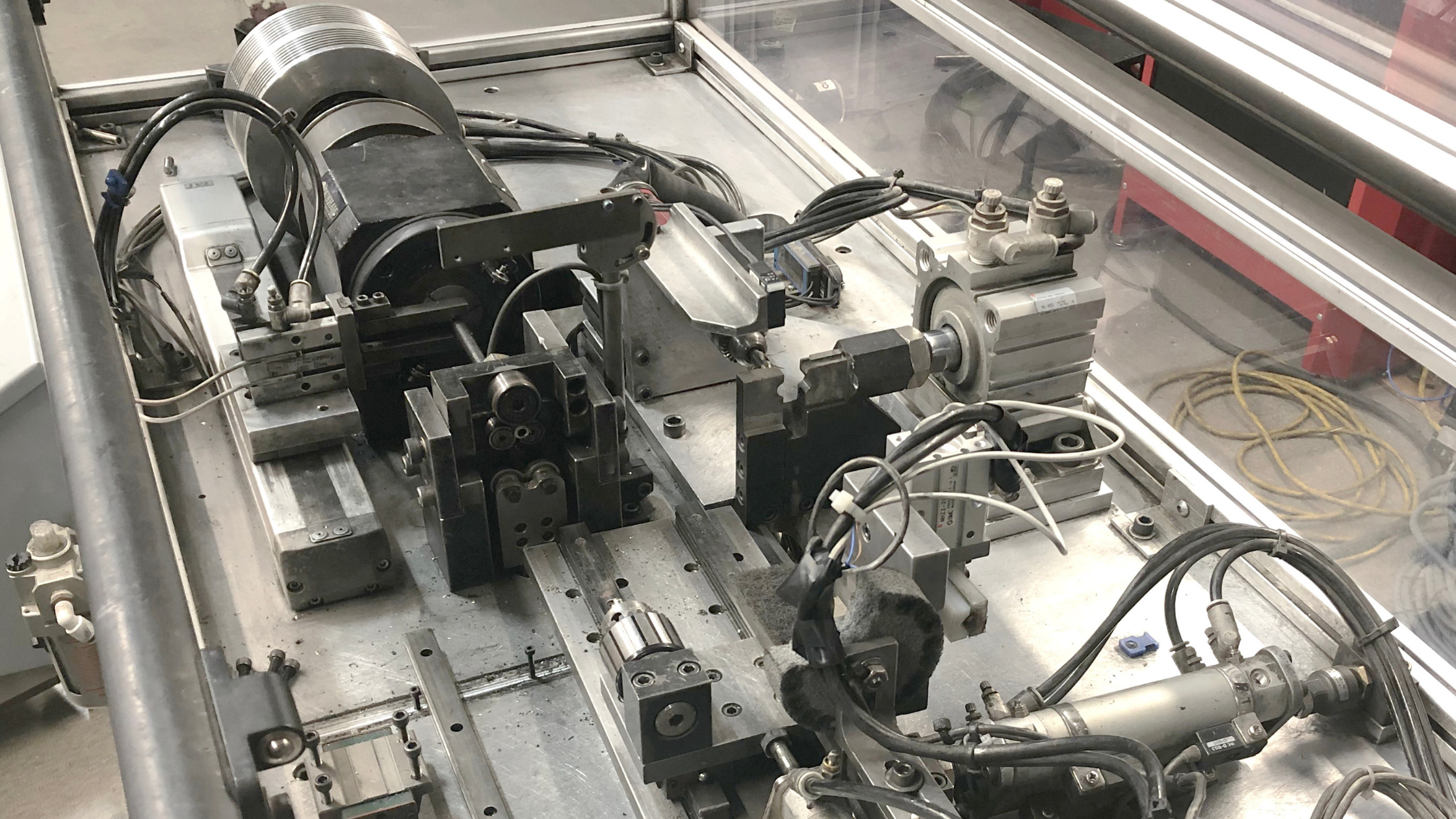

Our client’s new light industrial manufacturing machine starts by loading injection-molded plastic parts onto the feed conveyor. These parts are then singulated with an adhesive-backed paper UPC label at the in-feed conveyor escapement. From there, the parts continue down the conveyor to a side escapement where their height is checked with a thru-beam sensor.

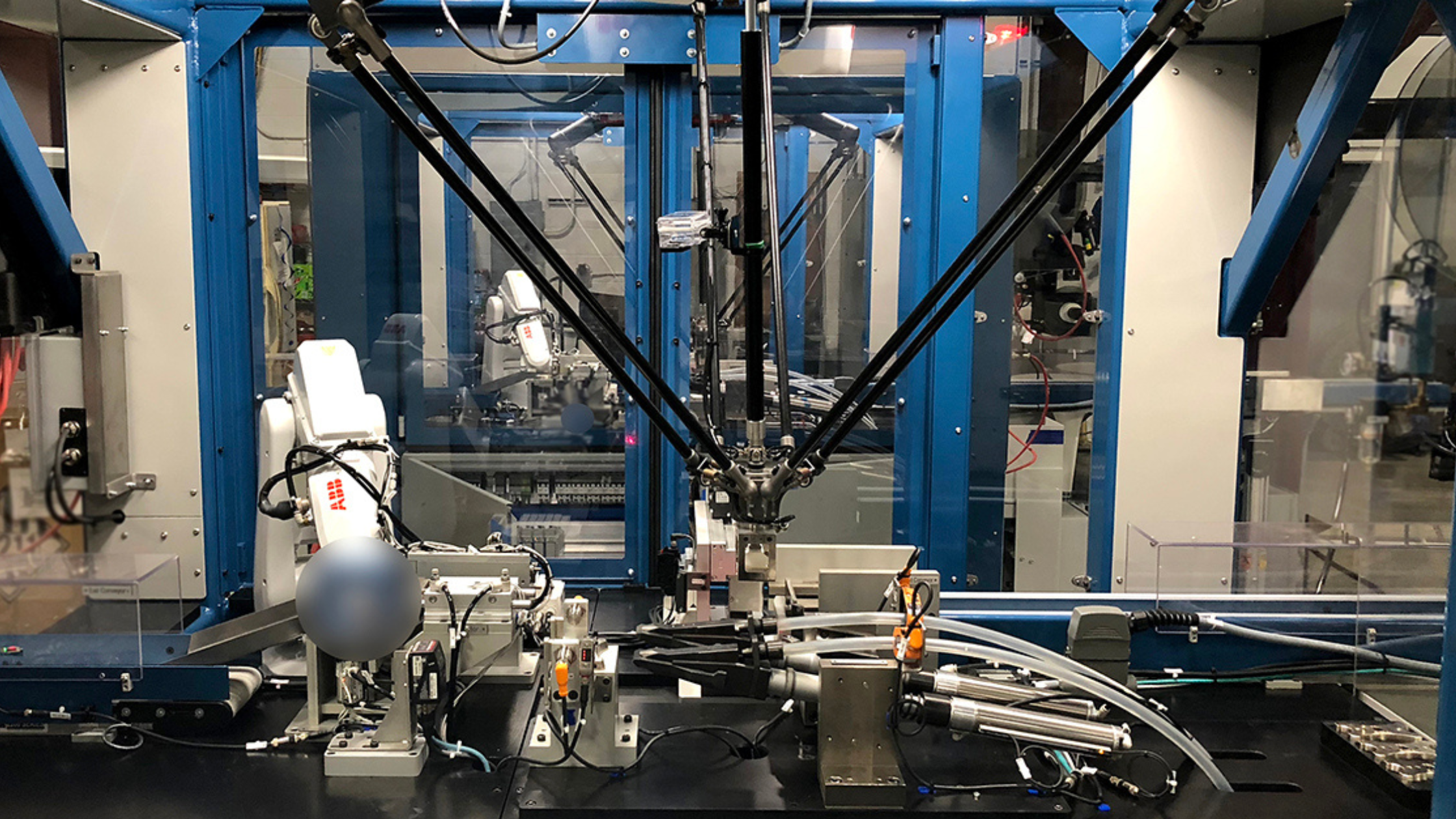

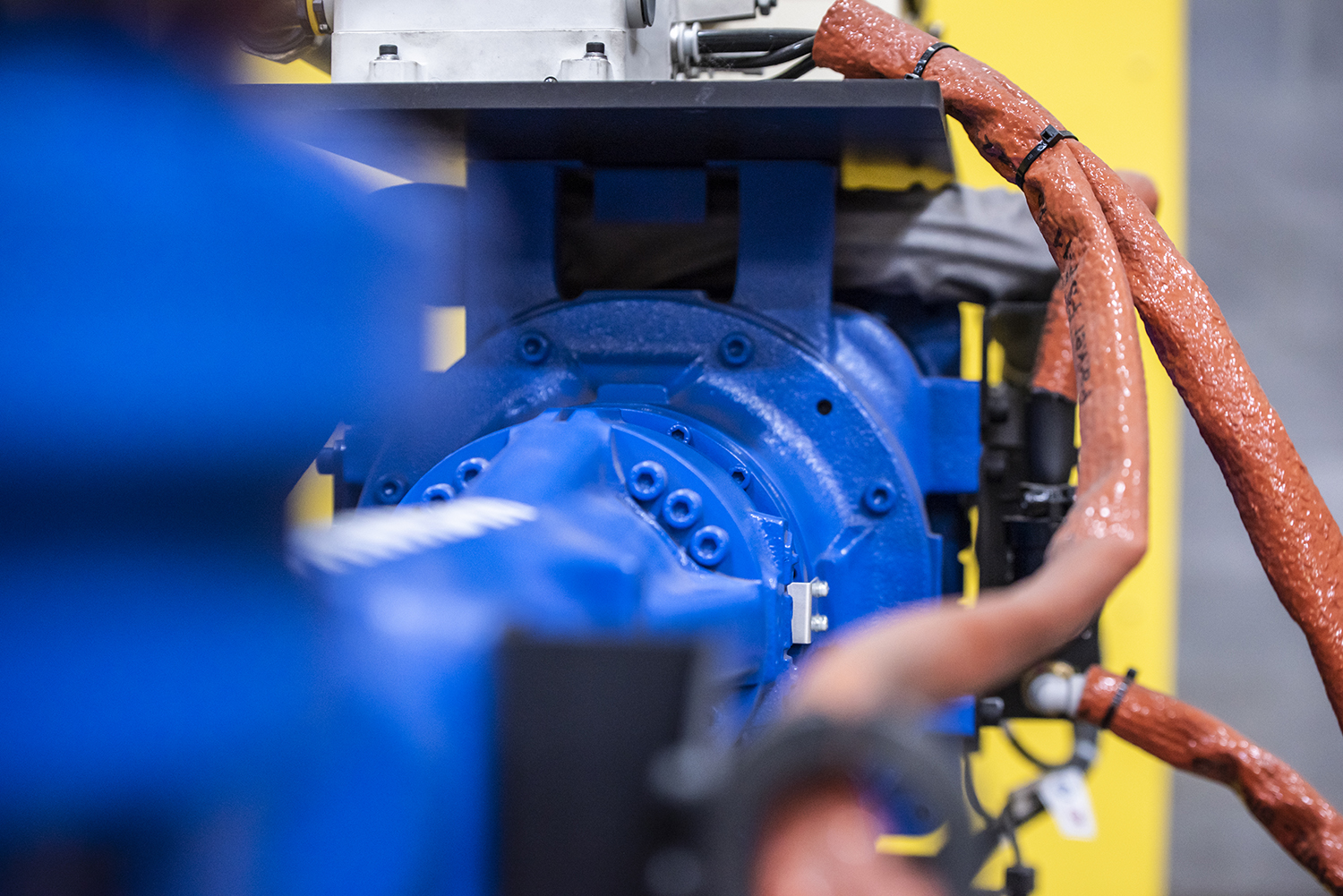

Once the height has been checked, an IRB 360 robot moves the part from the side escapement nest and places it on a nail insertion nest. There, nails are blow-fed and inserted into the part. Any box that fails the height inspection is dropped into the rejection chute. The UPC code is read and verified by a Keyence SR-750 barcode reader.

A vibratory feeder escapes the next nail into a blow-feed and nail insertion is verified by the machine’s sensors. The IRB 360 robot then moves the first part that’s passed inspection to an out-feed nest. The second part that passes inspection is moved to a flip-over nest. This part is picked up by an IRB 120 robot and is placed for interlocking with the first part. The interlocked boxes are sent down a chute onto an out-feed conveyor by the out-feed pusher actuator.

To learn more about our work in light industrial manufacturing, click here!

Analyzing the Results

Navus’s engineers were able to significantly improve our client’s output. Once completed, the new system was able to produce items at a rate of 24 finished parts per minute. This actually exceeded our client’s expectations and greatly simplified the part changeover process.

The new machine was easily integrated into the existing system thanks to the use of injection molding equipment and packaging conveyor systems. This enabled our client to save a considerable amount of time and money compared to other alternatives. It also works as a foundation for future layouts that won’t require changing their floor space requirements.

What is Light Manufacturing?

The light manufacturing industry covers a broad range of products so it can seem hard to define on the surface. However, the definition of light industrial manufacturing on its most basic level means:

the manufacture of products, the process of which does not create and emit fumes, gases, smokes, vapours, vibrations, noise or glare or other factors which are regarded as nuisances which would cause adverse effects to the users of adjacent land.

Most manufacturers can be classified as light industry. Light manufacturing industry examples can include:

- Consumer goods (e.g. office supplies)

- Durable goods (e.g. household appliances)

- Energy

- Electronics

The team at Navus are experts in light industry manufacturing as well as medium and heavy. We’re experienced in finding solutions for industries of all scales and sizes. With our 20+ years legacy, we have a proven track record of providing automated solutions for light industry manufacturers.

Do you need help finding solutions for your light manufacturing problems? Click here to contact us today!

We recently completed a project for a client who wanted to boost their production using automated processes. Our Navus engineers accomplished this task by partnering with ABB Robotics and CTM Labeling Systems to create a system that sorts the parts and puts them together. This increased our client’s throughput to 24 finished parts per minute with the option to have future layouts that won’t require changing their floor space requirements.

Navus Automation Inc. is a leading full-service automation integrator. Our world-class team has a reputation for applying ingenuity to solve complex challenges and deliver customized turn-key systems solutions. From concept to completion, Navus provides robotic welding and automation systems built upon our unwavering commitment to excellence, precision and reliability