Back to the Future With Navus

Navus has been envisioning a future for our clients since 1998. The majority of our clients are repeat customers, no matter the scale of their industry or our project. When we partner with a client, we don’t just deliver a system and then say goodbye. We deliver new ideas that lead to greater opportunities for our clients’ businesses. In a way, our clients have become an important part of the Navus family, and we love any opportunity to continue working with them.

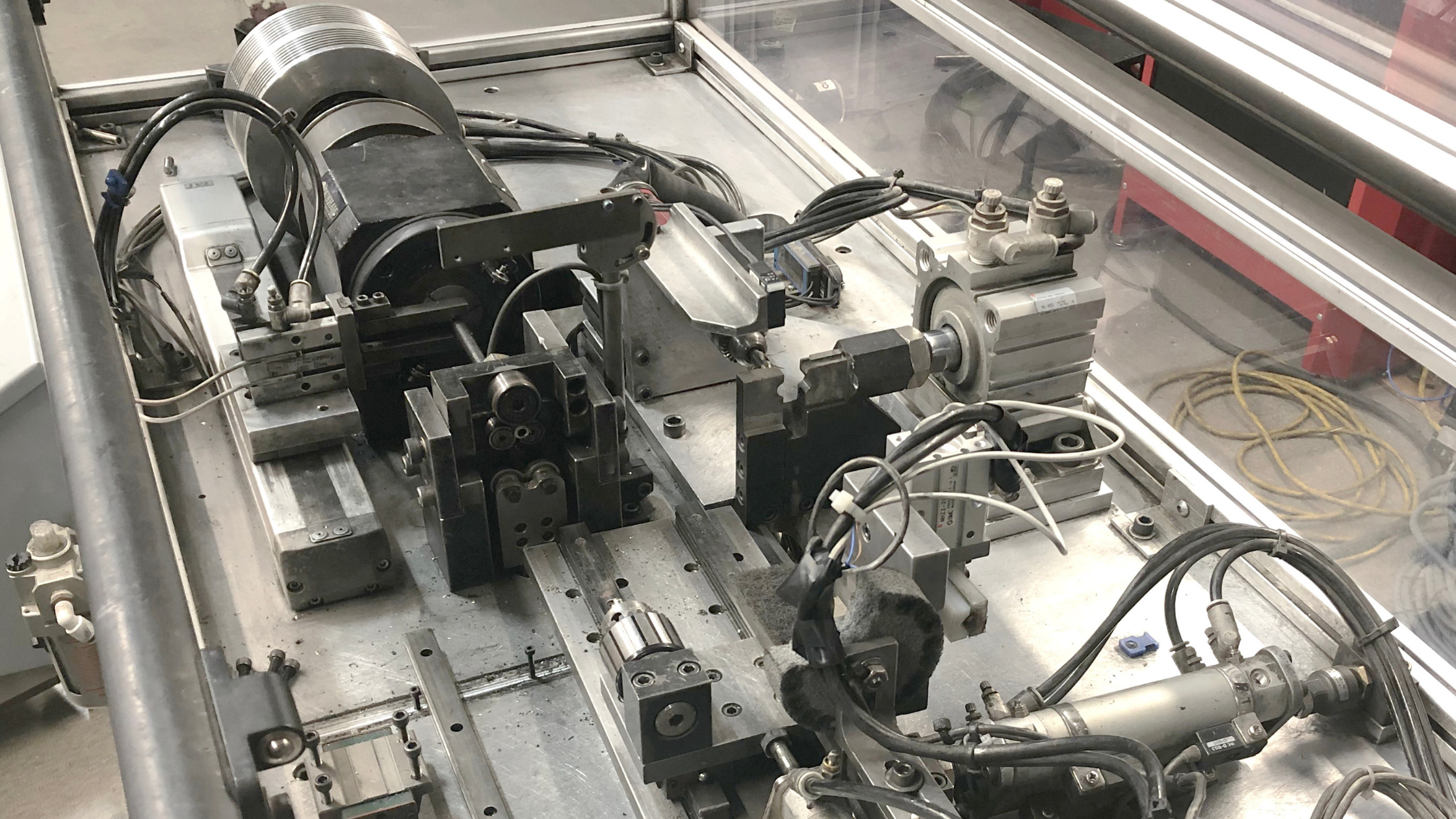

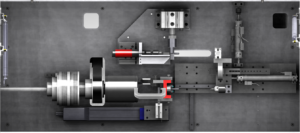

We recently had the rare opportunity to work with a customer on a machine we originally built for them 15 years ago! The machine was used on a consistent basis over the past 15 years to manufacture small parts in the medical industry, but it was clear they needed to either design a new machine or update the current one to meet their latest needs. Our team at Navus worked with our client to find the best solution for their needs. The result was our ability to revisit a piece of our company’s history, while solving a challenge for a valued client.

Should You Rebuild Your Current Machine? Or Invest in a New Machine?

Working in industrial manufacturing comes with a host of challenges and complexities on a regular basis, but our priority is always to find the perfect solution for your company.

When our client came back to us after 15 years of happily using the machine we originally built them, they came with a dilemma.

The machine they had used for the past 15 years to produce small parts for the medical industry worked the way they wanted it to. It produced legacy parts that are still relevant today, but there have also been important shifts and changes in the manufacturing world over the past 15 years. Our client wanted to know whether they should rebuild their current machine, or start over and invest in a new machine.

At Navus, we don’t just solve problems for our client — we partner with them to find the best solution for their needs. To solve our client’s dilemma, we started with a thorough evaluation of their current system. In order to make strong recommendations on their next step forward, we needed to understand the capacity at which they were currently operating, and what their goals for any future system would be.

Once our evaluation was complete, we delivered a detailed report weighing the costs and benefits of rebuilding their original machine versus building a completely new system. We’ve historically taken meticulous notes of how our solutions and systems are engineered. Referencing these detailed notes while we were evaluating our client’s system ultimately helped our client understand which option would work best for their goals.

Rebuilding Results in Peak Efficiency

The machines and systems that are on the production floor are an investment, and you want to invest in the systems that are going to bring you the best results. Our team’s initial step to evaluate our client’s current system ensured that we were considering the best outcome from multiple perspectives.

Our clients ultimately chose to rebuild the machine we previously built for them. They knew the system worked the way they needed it to, and it would only take a few updates to bring the machine in line with the 21st century.

From start to finish, the entire project was completed in 3 months. The end result was a machine rebuilt to exceed the original specifications, returned to our client in just a few weeks from starting the rebuild process. The new version of their machine runs at peak efficiency and continues to produce legacy products. Our client won’t have to worry about rebuilding or replacing this machine for years to come. It now does exactly what they need it to do, but even faster than before.

Engineering the Smartest Automation Solutions Since 1998

Navus’ ability to solve our clients’ challenges ultimately comes down to our team and history of excellence. Every one of our engineers is passionate about solving specific challenges for our clients who partner with us. At Navus, we don’t resort to the same solution other integrators offer. We’re dedicated to thinking outside of the box to ensure our turn-key system solutions accomplish what our competitors haven’t considered.

Partnering with Navus isn’t just about figuring out a solution for your current challenges. We promise to offer new ideas and solutions that create a better future for your manufacturing space and company.

Navus Automation, Inc., is a leading full-service automation integrator. Our world-class team has a reputation for applying ingenuity to solve complex challenges and deliver customized turn-key systems solutions. From concept to completion, Navus provides robotic welding and automation systems built upon our unwavering commitment to excellence, precision, and reliability.

For more information on how our team can help you solve complex challenges in your manufacturing facility, reach out to us today!