Solving Production Delays & Programming Issues

No matter what’s being produced, the manufacturing process can get complicated quickly. Every one of our manufacturing clients come to us with unique challenges somewhere in their process—including programming issues. Recently, a client approached us with recurring challenges they were facing in their manufacturing process due to the architecture of their control systems and its inability to do what they needed to without manual input. They needed a reliable system that could improve overall production and make it easier to operate.

There’s a reason we claim to solve complex challenges — our team is known for solving the challenges that our clients face. We’ve proven it time and time again. No matter the scale of the challenge you’re facing, our team works until they find a unique solution that works better for than you could have ever imagined.

Programming Issues Can Cause a Host of Production Problems

It seems simple enough, but if a system in your manufacturing facility isn’t programmed correctly, it’s almost impossible for the entire production system to do what it’s supposed to do. This understandably causes more than one problem in your facility. Production rates plummet, processes are stalled, it feels like something’s always in need of fixing, and it leaves you and your entire team with a major headache and no clear fix.

That’s the moment our engineers come to your rescue.

The featured client was dealing with all of the above frustrations when they approached us for a solution. Our engineers know the ins and out of a control system’s architecture, which allowed us to recreate the system they already had, but in a way that actually worked for them.

How did we do it?

The Navus Solution: Getting Back to the Architecture of it All

By going back to the root of what our clients needed their system to accomplish, our team was able to build a better, more efficient system. All aspects of the production line needed to understand and communicate with each other. Our client didn’t just need automation for automation’s sake— they needed a smart solution that actually did everything their production process required without constant input from operators.

By going back to the root of what our clients needed their system to accomplish, our team was able to build a better, more efficient system. All aspects of the production line needed to understand and communicate with each other. Our client didn’t just need automation for automation’s sake— they needed a smart solution that actually did everything their production process required without constant input from operators.

Our client was continuously faced with the challenge to produce a consistent fit up, within a tight tolerance, on a multi-part assembly at a critical place within their manufacturing process. One missing piece in their previous system keeping them from accomplishing this was the ability to automatically recognize and compensate for part features and variables. This is a feature we’ve delivered to other clients before, including the project detailed in our white paper: MAKING THE IMPOSSIBLE POSSIBLE WITH SENSOR-GUIDED ROBOTICS. Because of our experience and reputation for delivering our clients systems that can identify their different parts, and intuitively know what to do with the parts, we knew we could deliver this particular solution.

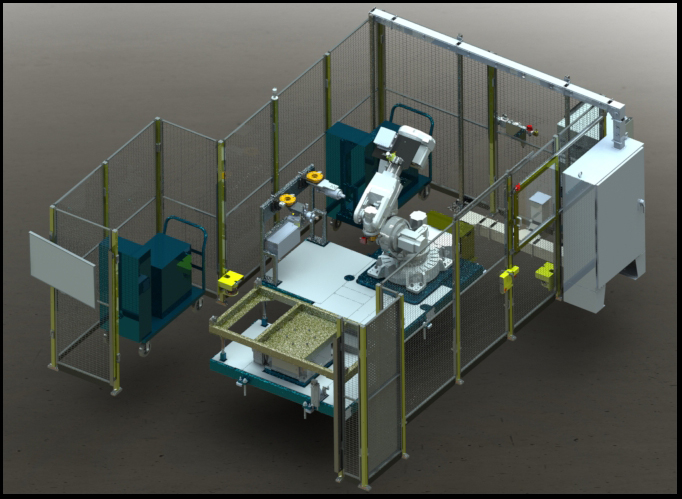

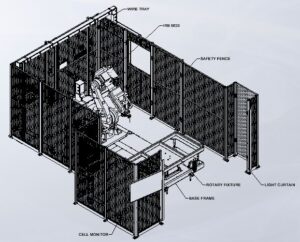

Navus’ system was able to automatically overcome the variable tolerance stack ups in materials and assembly without the need for operator intervention or input. Due to Navus’ depth of knowledge in control system’s architecture, we were able to recreate a production cell that our client was familiar with. We weren’t trying to make their new system fit in their existing floorspace. We simply took the concept of what was already there, made it infinitely better, and integrated it into their facility seamlessly.

The ultimate result? Dramatically improved production rates and reliable part consistency to the downstream process. It was an easier system for operators to manage because it didn’t produce inconsistencies, slow production down with stalled time, or require constant tweaks and manual operation. Now all the operators have to do is oversee that the system is doing what it’s supposed to.

Automation Integration is Considering the Big Picture

When Navus goes to solve a challenge for a client through automation integration, we look at the big picture. We ask ourselves how the process we’re creating for you is going to work with the rest of your facility. Our solutions are built to communicate with the rest of your manufacturing process, and fit into the space you already have.

We promise to deliver solutions that work, and we don’t end the relationship once the process has been delivered. We pride ourselves on our client relationships and love to find other ways we can solve the challenges our clients face.

Navus’ ability to solve your challenges ultimately comes down to our team and history of excellence. Every one of our engineers is passionate about solving specific challenges for our clients who partner with us. We’re dedicated to thinking outside of the box to ensure our turn-key system solutions accomplish what you need and solve the challenges you face. From electrical and controls system engineering to automation integration, and everything in between, we promise to partner with you in all aspects possible. When you choose to partner with us for your integration needs, you become a part of the Navus family.

Navus Automation, Inc., is a leading full-service automation integrator. Our world-class team has a reputation for applying ingenuity to solve complex challenges and deliver customized turn-key systems solutions. From concept to completion, Navus provides robotic welding and automation systems built upon our unwavering commitment to excellence, precision, and reliability.

For more information on how our team can help you solve complex challenges in your manufacturing facility, reach out to us today!